Plastering engineering is an indispensable part in decoration.General plastering work refers to the application of lime mortar, cement mortar, cement mixed mortar, polymer cement mortar, knife lime, paper reinforced lime, gypsum plaster, etc. on the wall surface of buildings(Including concrete, brick setting, aerated concrete, building blocks).

Based on the site examples, the paper interprets the "seven steps" construction process, material technology and construction environment requirements of plaster work, which can be used for reference and implementation.

1. Construction process

The construction process of plaster work can be summarized as seven steps: ① base treatment → ② watering and wetting → ③ Ash cake → ④screed→ ⑤ layered plastering → ⑥dividing joints setting → and (7) finished products protecting.

① Base Treatment

(1)Base cleaning.

The quality of base is an important factor affecting the quality of building decoration. Before plastering work, the dust, dirt and oil stains on the surface of the base course shall be cleaned . And The surface

of brick masonry shall be cleaned and be watered before plastering; the concrete surface shall be roughened or sprayed with 1:1 cement mortar (with appropriate amount of adhesive) after the surface is moistened; after the aerated concrete is waterd, the interface agent shall be applied while the cement mixed mortar with strength no less than M5 shall be applied. The parts with obvious concave convex surface shall be leveled or filled with 1:3 cement mortar in advance.The plastering work shall be carried out after the quality acceptance of the base.

(2)Strengthening measures for unconventional plastering.

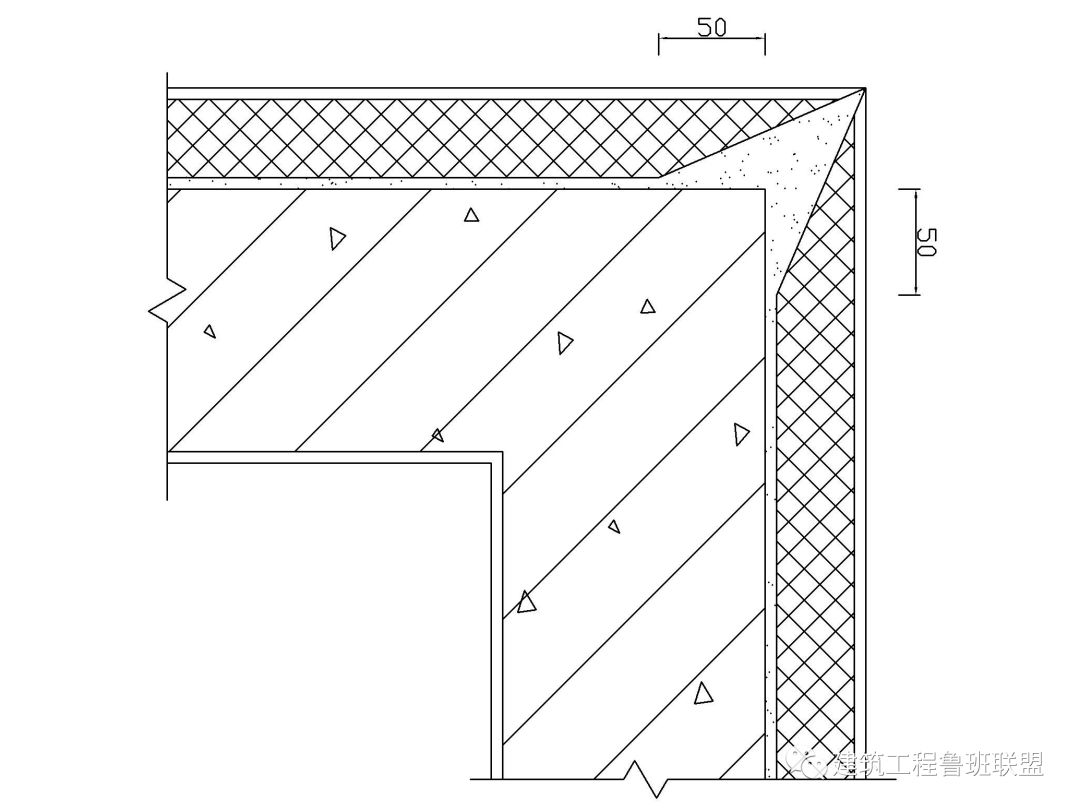

When the total thickness of plastering is greater than or equal to 35mm, strengthening measures should be taken. Strengthening measures to prevent cracking shall be taken for plastering at the joint of different materials. When the reinforcing net is used, the lap width between the reinforcing mesh and each building shall not be less than 100 mm. The reinforcing net should be tightened and nailed firmly.

Before the construction of external wall plastering works, the door & window, and frames, guardrails should be installed, and the construction holes should be sealed. The construction of indoor wall surface, column surface and door opening shall meet the design requirements. When there is no design requirement, 1:2 cement mortar shall be used as concealed angle protection, the height shall not be less than 2m, and the width on each side shall not be less than 50mm.

Generally, one day before plastering, the worker should water the wall with water pipe or spray pot from top to bottom. Different walls and different environments require different watering amount. Watering should be carried out in stages, and the wall should be wet and not bleeding.

③ Vertical lifting, set angles and squares, plaster ash cakes

The worker should base on the plastering quality required by the design drawings and the smoothness and verticality of the base surface, using a wall as the benchmark. And the plastering thickness is determined by the ash cake. During operation, the top ash cakes should be plastered first. When plastering the cake, the correct position of the plaster cake shall be determined according to the indoor plastering requirements, and then the guiding rule plate shall be used to find the vertical and flat. 1:3 cement mortar should be used to plaster the ash cake into a square shape of 50mm. When the room area is large, the cross center line should be first snapped on the ground, and then the corner line should be drawn according to the flatness of the base surface. The plumb line should be hung and the plumb line should be ejected at the place 100 mm away from the inner corner of the wall. Then, the wall plastering layer thickness control line of the two walls at the internal corner should be drawn according to the wall corner line on the ground, so as to make the ash cake, and then do the screed work base on the ash cakes.

④ Wall reinforcement

When the ash cake mortar reaches 70% to 80% dry, it can be filled with the same mortar as the plastering layer. The number of reinforcement bars should be determined according to the width and height of the room. Generally, the width of the standard reinforcement is 50 mm. The spacing between the two bars shall not be greater than 1.5m. When the height of the wall is less than 3.5m, fill the reinforcement vertically, or fill the reiforcement laterally, but the space between t ash cakes shoul less than 2m.

⑤ Layered Plastering

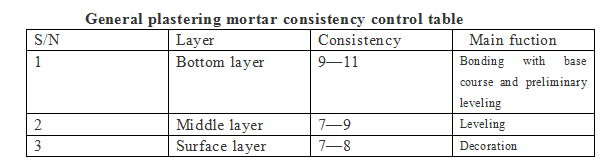

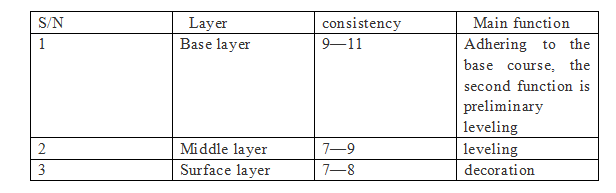

Before large area plastering, standard bars should be set. Plastering works shall be carried out in layers. Generally, the plastering structure is divided into bottom layer, middle layer and surface layer. The specific technical requirements refer to the table below. Among the specific, the cement mortar shall not be plastered on the lime mortar layer; the gypsum plaster on the surface shall not be plastered on the cement mortar layer.

When plastering with cement mortar and cement mixed mortar, the latter layer can be plastered after the former plastering layer is set; when plastering with lime mortar, the latter layer can be plastered after the former plastering layer is 70% to 80% dry. The strength of the plastering layer of the bottom layer shall not be lower than that of the surface layer. After mixing, the cement mortar shall be used up before the initial setting, and the hardened mortar shall not be used again.

The plastering layer must be firmly bonded with the base course and between each plastering layer. The plastering layer shall not be completed with delamination, hollowness, and the surface layer shall not be completed with explosive ash and cracks.

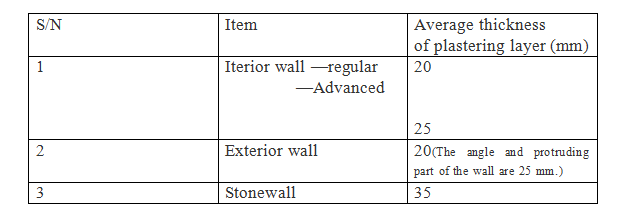

The average total thickness of the plastering layer shall meet the design requirements. Generally, the thickness of each layer of plastering structure should be 5 to 7mm, and that of lime mortar and cement mixed mortar should be 7 to 9mm. When there is no design requirement, the average total thickness of plastering layer shall not be greater than the requirements in the table below.

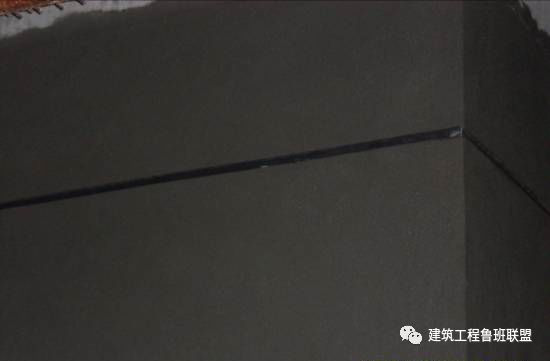

The setting of the plastering dividing seam shall meet the design requirements, the width and depth shall be uniform, the surface shall be smooth, and the edges and corners shall be neat.

⑥Set up dividing seam

Drip line (trough) shall be made at the parts with drainage requirements. The drip line (trough) shall be neat and straight, the drip line shall be high inside and low outside, and the width and depth of the drip line shall not be less than 10 mm.

⑦ Finished parts protection

All kinds of mortar plastering layer shall be prevented from quick drying, water flushing, impact, vibration and freezing before setting, and measures shall be taken to prevent contamination and damage after setting. The cement mortar plastering layer shall be maintained under wet condition, and generally it shall be maintained after plastering for 24h.

2. Material technical requirement

①cement

The strength grade of cement used for plastering shall not be less than 32.5MPa, and the inspection of setting time and stability of cement shall be qualified. Cement of different varieties and strength grades shall not be mixed.

② Sand

Medium sand should be selected, and the sand should be screened (the hole diameter of the mesh should be less than 5 mm ) before use, and no impurities are allowed; ultra fine sand should not be used.

③Lime paste

The curing period of lime paste used for plastering shall not be less than 15d; the lime paste shall be fine and white, and shall not contain unhealed particles; the frozen and weathered lime paste shall not be used.

④Colored stone

Color stone is broken from natural marble, with a variety of colors, mostly used as aggregate of terrazzo, water brush stone and cut stone.

Specification, variety and quality requirements of colored stone.

⑤ Mix proportion of mortar

General plastering mortar consistency control table.

3. Construction environment requirements

①The plastering work can should be carried out after the main structure is accepted by relevant departments.

②Check whether the door and window frames and the distribution pipes, junction boxes and pipe sleeves to be buried are firmly fixed, whether the connection gap is embedded in the chamber, and wrap the door and window frames in advance.

③The plastering surface of concrete components shall be treated, and a layer of plain cement slurry shall be applied, and then 1:2.5 cement mortar shall be used for leveling and compaction in layers.

④The position and elevation of curtain hook, ventilation grate, wall cabinet, ceiling fan and other embedded parts or bolts shall be set accurately, and anti-corrosion and anti rust work shall be done well.

⑤The sand dust, dirt and oil stains on the surface of concrete and brick structure shall be removed, and the surface of concrete structure and brick wall shall be watered 2 days before plastering.

⑥Before the roof waterproof work is finished, the waterproof measures should be taken.

⑦The ambient temperature of indoor plastering shall not be lower than 5 ℃, otherwise effective measures shall be taken to ensure the quality.

⑧Before plastering, it is necessary to be familiar with the drawings, specify the plastering scheme, and then the sample should be plastered . The construction can be carried out in large area only after the qualified standard is met the requirements.

previous:

Qualification Certificate Renewing for Construction Enterprisesnext:

sorry, this is the last。 Add:

Add: